After a disappointing series of block letter ‘A’s last week I realised my basic bends were letting me down. Basic bends are like the letters of the neon bending alphabet: they’re the heart of neon glass work, and being able to make them accurately and consistently is crucial to making clean, correct looking letters.

Depending on who you ask there are a different number of basic bends, and they all have different names. In truth they are pretty much the same everywhere: it’s just that there are different names in use and people find different ways of counting them.

Some of the names you’ll find for similar bends include:

- L bend, 90 degree bend, right angle

- U bend, doubleback, turnaround

- V bend, offset, angled doubleback

- Raise / drop

- Curved bend

- Combination bend

There are plenty of more complex bend styles that are used both in sign work and neon art including several methods of producing a mitred bend: a sharper, more visually pleasing appearance at the apex of the bend.

I’m not going to go into any of those here because every time I attempt them I end up holding a twisted wreck of glass.

Double trouble

It was the doubleback in the middle of the ‘A’ that was bugging me: no matter how much I tried, they kept coming out bulging on one side, or offset so that the ‘back’ tube was partly visible from the front.

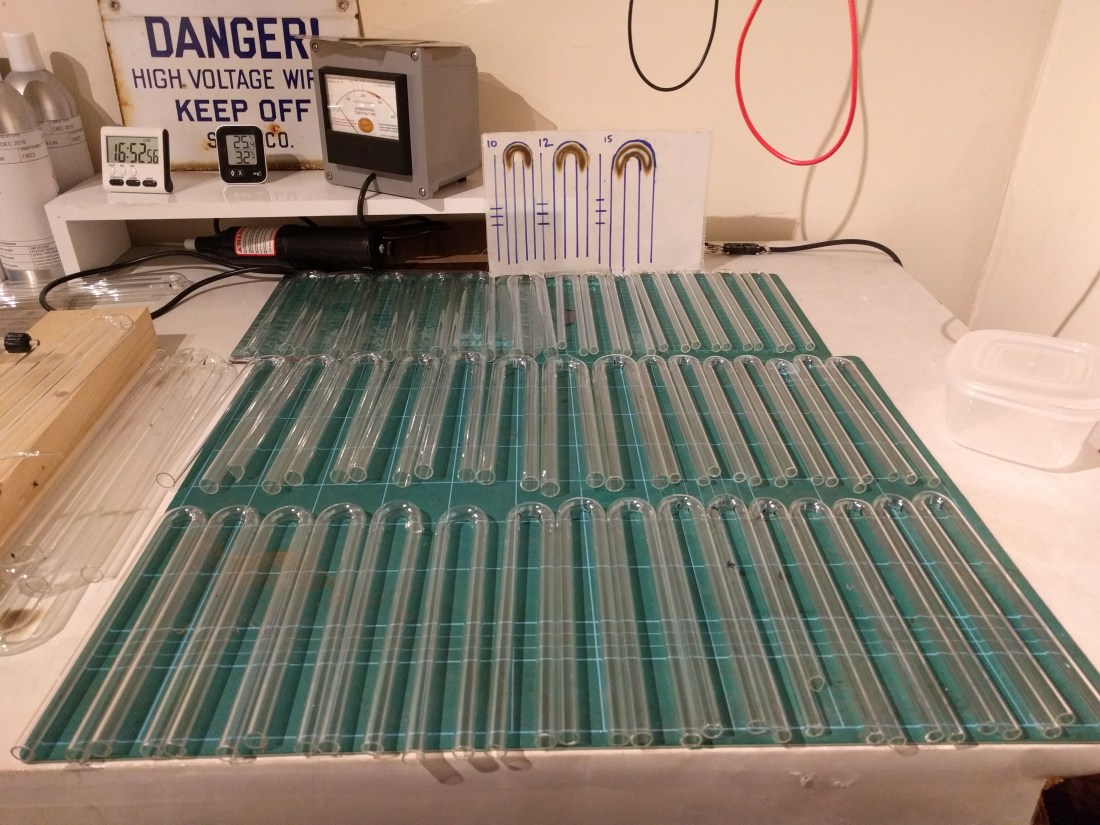

The ‘A’ is a little harder than a doubleback in straight tubing as you’re one bend in already, so I decided to break it down a bit and have a couple of days just practising the doubleback on its own.

Since I’m still pretty much a beginner I have some little tweaks in the workshop to make this sort of work a bit quicker: for basic bend practise I normally use around a 16″ (400mm) length of tubing. I find it’s a comfortable size to handle and you can get three to a standard European 1500mm stick (plus a foot long offcut for splicing practise).

There are marks on the bench at 8″ intervals, and on one of them there are marks for the doubleback and other bends (2x, 2.5x and 3x diameter). There are also marks in mm across the edge of the bench for cutting longer pieces: it saves getting a tape measure out when you don’t need to be super accurate.

To cut a bunch of sticks for practise I line up one of the lines on the cutting matt with the length I want, line the stick up with the edge of the bench and scratch.. snap.. scratch.. snap.. You can quickly cut and mark enough glass to keep you busy for a few hours that way and you don’t need to go back and switch your attention all the time.

The pattern I use is taken from a 15mm master, printed out at 100%, 80% (12mm) and 67% (10mm), and then traced onto pattern cloth by hand with a Sharpie. The marks down the edge give the correct marks for the doubleback (actually, for my money these are a bit tight – they’re taken from the original, but they’re only about 2x the tube diameter. I tend to use more like 2.5x now).

Case of the bends

Even the humble doubleback has plenty of scope for trouble. There are a number of common errors that each affect the finished bend in different ways. Some of these, like overblowing, can happen in any bend. Others are more particular to the doubleback, or at least affect it in particular ways:

- Twisting one or both of the ends either ‘in’ or ‘out’ of the bend

- Bend bulges out along the apex of the bend on one side and leans in on the other. Looking side-on the apex of the bend looks ‘pinched’ or ridged. Wobbles when placed on bench.

- Check the marks: are they facing one another and centred, or is one or both turned off centre?.

- ‘U’ of the bend is uneven

- Bend radius is smaller on one side than the other, or one side is ‘pinched’ and uneven. Outside marks are not at the same level. Trying to ‘fix’ by stretching thins the glass unless the error is quite small.

- Ends are not parallel, arch of bend may seem twisted or tube bends at an angle as it exits bend: hands were either out of alignment during the bend (twisted arch), or moved after the bend was made (kink exiting bend).

- Bend is stretched in the arch

- Bend appears more like two adjacent ‘L’ bends than a smooth, continuous arc.

- Glass is thinned in between the ‘L’s.

- Not enough glass was heated.

- Straight glass exists between either outer mark and the centre mark.

- Bend seems pinched and too narrow

- Not enough glass was heated.

- Glass bunches in the middle of the bend at the centre mark

- Glass is too thick on the inside and probably too thin on the outside

- Glass was not hot enough

- Glass “wobbly” and bulges around the end

- Glass was too hot, or air was blown in too hard

Marks out of ten

Normally I use a soft graphite pencil to mark clear glass. It gives a faint but visible mark even in the torch flame but it can be tricky to see at times. For a lot of these I went back to using black grease pencil, the idea being it’s a clearer mark and easier to see in the flame.

I’m not sure now that it was really much benefit: it does persist better in the flame (part of the reason it’s not popular is that it can react with the surface of the glass, leaving a permanent mark), but it’s also smudgier and less distinct – it’s hard to keep a point on the pencil that will give a good crisp mark and sharpening it all the time just makes a mess.

I went back to the graphite by the end of today’s session. The sharpness of the marks really matters when you’re trying to judge whether a mark has been twisted: a fuzzy blob isn’t much help.

Deliberately defective

As well as accidentally making lots of bends with errors, I made a couple towards the end with deliberate mistakes: partly to get examples to photograph, and partly to get a feel for what not to do. The tubes in the photographs all have mistakes. The 15mm is a three-in-one bonus: it’s twisted, offset, and overblown. I totally planned to do that. Honest.

And finally

As with mastering any complex motor skill, repetition is the key to getting the basic bends right every time. It’s not the most exciting thing you can do in a neon shop but drilling the bends, at least for a few hours or so at a time, definitely gives you a boost when you go back to bending more complicated patterns.